MIL-DTL-25427B

4.6.3 Noncompliance. If a sample fails to pass inspection, the manufacturer shall

immediately notify the qualifying activity and the cognizant inspection activity of such failure

and corrective action shall be taken. Full particulars concerning action taken to correct the

defects shall be submitted to the qualifying activity and the inspection activity. Acceptance and

shipment of the product shall be discontinued until corrective action acceptable to the qualifying

activity has been taken. After the corrective action has been taken, inspection shall be repeated

with additional sample units. Inspections may be continued; however, final acceptance and

shipment shall be withheld until final inspection has shown that the corrective action was

successful. In the event of failure after re-inspection, information concerning the failure shall be

furnished to the cognizance inspection activity and the qualifying activity.

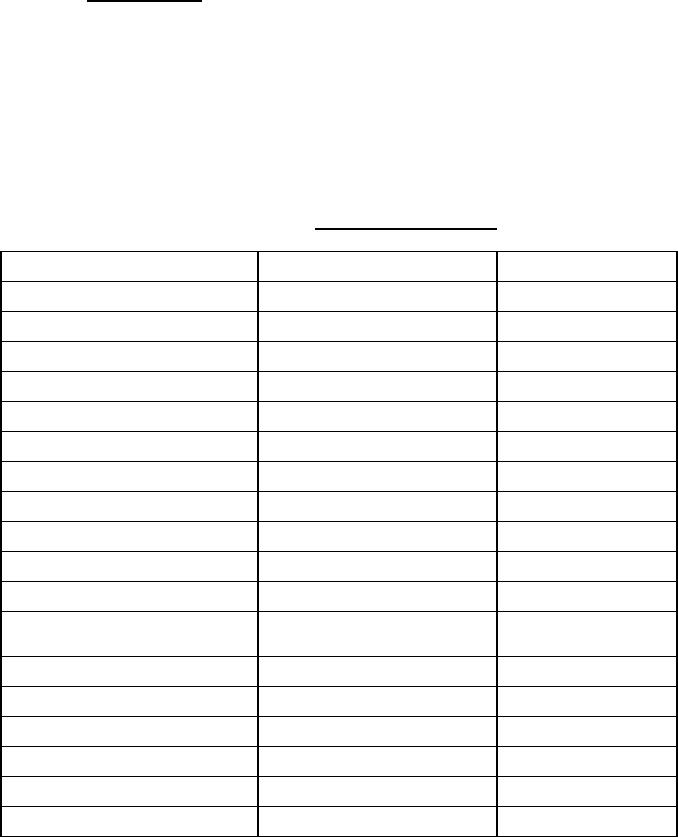

TABLE V. Qualification inspections.

Inspection

Requirement paragraphs

Test paragraphs

Examination of product

3.6, 3.8 and 3.9

4.8.1

Manual operation

3.7.2

4.8.2

Immersion

3.7.3

4.8.3

Air inclusion

3.7.4

4.8.4

Leakage

3.7.5

4.8.5

Pressure drop

3.7.6

4.8.6

Vacuum

3.7.7

4.8.7

Extreme temperature functioning

3.7.8

4.8.8

Rapid warm up

3.7.9

4.8.9

Proof pressure

3.7.10

4.8.10

Surge flow

3.7.11

4.8.11

Impulse and vibration (1000 and

3.7.12

4.8.12

3000 psi only)

Impulse (5000 psi only)

3.7.13

4.8.13

Vibration (5000 psi only)

3.7.14

4.8.14

Shock

3.7.15

4.8.15

Burst pressure

3.7.16

4.8.16

Flange strength

3.7.17

4.8.17

Endurance

3.7.18

4.8.18

11

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business